We Work With

About Us

A multidisciplinary 3D design studio, with a focus on bringing designs to life. We specialise in creating captivating visuals and design assets that elevate products and drive consumer engagement.

With roots in industrial and footwear design, our expertise goes far beyond aesthetics. We offer technical know-how across the full product lifecycle; from concept development and manufacturing support to photoreal visualisation.

Take a look at our footwear design, development, & sourcing services

PRODUCT DESIGN

PRODUCT VISUALISATION

3D RESOURCES

Services

PRODUCT DESIGN

PRODUCT VISUALISATION

3D RESOURCES

UK DESIGN & DEVELOPMENT TEAM

VIETNAM SOURCING & PRODUCTION

PERFORMANCE FOOTWEAR

LIFESTYLE SNEAKERS

Our Team

Carl

Director

Brian

Creative Director

Julian Good

Operations Director

Rebecca

Design Lead

Chris

Senior Design

Cameron

Designer

Lewis

3D Designer

Kian

Junior Developer

Johnny

Vietnam Development Manager

Thuy

Developer

Thanh

Material Developer

Galvin

Quality Control Manager

Production

Trend & Research

Creative Direction

We offer expert Creative Direction that shapes and elevates your brand’s visual identity. From concept to execution, we ensure every creative element aligns with your brand strategy and resonates with your audience. Our services include brand storytelling, visual identity development, campaign direction, and cross-platform design consistency. We collaborate closely with clients to craft compelling, cohesive, and strategic design solutions. Whether launching a brand or evolving an existing one, our creative leadership drives clarity, impact, and growth. Let us guide your vision and bring it to life through inspired, results-driven design direction.

Product Design

We specialize in design driven by innovation, creativity, and industry insight. Our team delivers cutting-edge solutions that merge functionality, trend-driven aesthetics, and advanced material design to meet the demands of modern consumers. From high-performance shoes to hybrid lifestyle models, we create footwear that balances style, comfort, durability, and sustainability. Using in-depth trend analysis and creative problem-solving, we guide each project from concept to production-ready design. Whether you're launching a new line or evolving an existing product, we deliver forward-thinking footwear design that stands out in today’s fast-paced, competitive market.

Tech Packs

We create precise, factory-ready footwear tech packs and specification sheets that streamline the production process. Our detailed technical documents clearly outline how each component—whether an upper, outsole, or full shoe—should be constructed to match the design intent. With a strong focus on accuracy, clarity, and industry standards, our tech packs help ensure your product is built right the first time. By combining expert design knowledge with manufacturing insights, we minimize errors, improve communication with factories, and deliver consistent, high-quality results. A well-executed tech pack leads to better footwear—and we make sure yours is production-ready.

Manufacturing

Cutting

Stitiching

No Sew

Printing & Treatments

Lasting

Assembly

Quality Control

Production

Manufacturing

Discover premium footwear manufacturing in Vietnam, where high-quality production meets innovation and refined lifestyle design. Our HIGG audit-approved, ISO 1500 & ISO 1501 certified factory delivers performance-level footwear with a 120-day production lead time. We combine advanced technology, skilled craftsmanship, and rigorous quality assurance to create shoes that excel in durability, comfort, and style. Whether you're developing high-performance athletic shoes or elevated lifestyle collections, our Vietnamese facilities provide scalable, sustainable, and dependable solutions. Trusted by global brands, we deliver refined footwear that aligns with modern consumer expectations for quality, innovation, and ethical production. Partner with Vietnam’s leading manufacturer today.

Cutting

Footwear pattern cutting is the first crucial step in manufacturing, ensuring accuracy and consistency. Using cutting dies and advanced laser cutting machines, we achieve precision engineering for every component. This process sets the foundation for quality footwear production, combining traditional techniques with modern technology to deliver efficient, high-precision cuts across a wide range of materials.

Stitching

Footwear stitching is expertly executed by highly experienced machinists using precision machines. From cut-and-sew designs to complex assemblies, every stitch reflects quality craftsmanship and attention to detail. Our skilled team ensures strong, durable construction that enhances both fit and style, delivering consistent, high-quality results that meet the demands of modern footwear design and production standards.

No Sew

The no-sew heat press process is ideal for highly technical footwear, offering clean, durable finishes without stitching. Using advanced TPU and PU heat pressing machines, we achieve seamless bonding for modern, performance-driven designs. This innovative method ensures precision, strength, and efficiency—perfect for athletic and lifestyle footwear requiring lightweight construction and a sleek, high-tech appearance.

Printing and treatments

Footwear printing and treatments include techniques like screen printing and sublimation printing for vibrant, durable designs, Advanced techniques like 3D and 4D printing, silicone are also used to offer more depth in design. Post-application finishes such as metallic plating and electroplating add premium detail and texture. These innovative processes enhance the aesthetic, delivering customized, high-impact footwear for your brand.

Lasting

The footwear lasting process shapes the final form of the shoe, ensuring fit and structure. We specialize in strobel, board lasting, and board lasting toe techniques to suit various footwear styles. Each method is expertly executed for durability, comfort, and performance, forming a solid foundation for high-quality, professionally finished footwear ready for market.

Assembly

The footwear assembly process involves precisely fitting the outsole and upper using molded jigs and pressing at controlled temperatures for optimal bonding. This ensures accurate alignment, strong adhesion, and long-lasting durability. Combining expert craftsmanship with precision engineering, our method guarantees high-quality, performance-driven footwear that meets exacting standards for comfort, function, and aesthetic appeal in every pair.

Quality Control

Providing end-to-end quality control to ensure every pair of footwear meets the highest standards. From material inspection to final product checks, each step is carefully monitored to align with the approved gold seal sample. Our experienced quality team works closely with factories to maintain A-grade production, identifying and resolving issues early through regular in-line inspections. With a strong presence in Vietnam, we ensure consistency, precision, and reliability across every production run—delivering footwear that meets your brand’s performance, quality, and customer satisfaction expectations.

Testimonials

Mark Quaradeghini. LOCI Co-Founder and COO

Working with Chris and the team at Locol on 3D development has been a game-changer. The ability to visualise and iterate designs in real time — whether showcasing creative options, refining tooling details, or presenting polished concepts to major retailers — has significantly elevated our process. Their 3D capabilities have not only accelerated decision-making but also delivered major cost savings by reducing the need for multiple physical samples. Their 3D capabilities have made sample rounds faster, smarter, and more collaborative.

Scott Portzline. HOLO Principal Designer & Creative Director

Working with Chris and the team has been a pleasure. Their ability to execute design intent while simultaneously elevating the overall product aesthetic is huge. Fast, accurate, responsive and flexible. True 3D pros. Would recommend.

Emelia Funnell. IDA Product R&D Lead

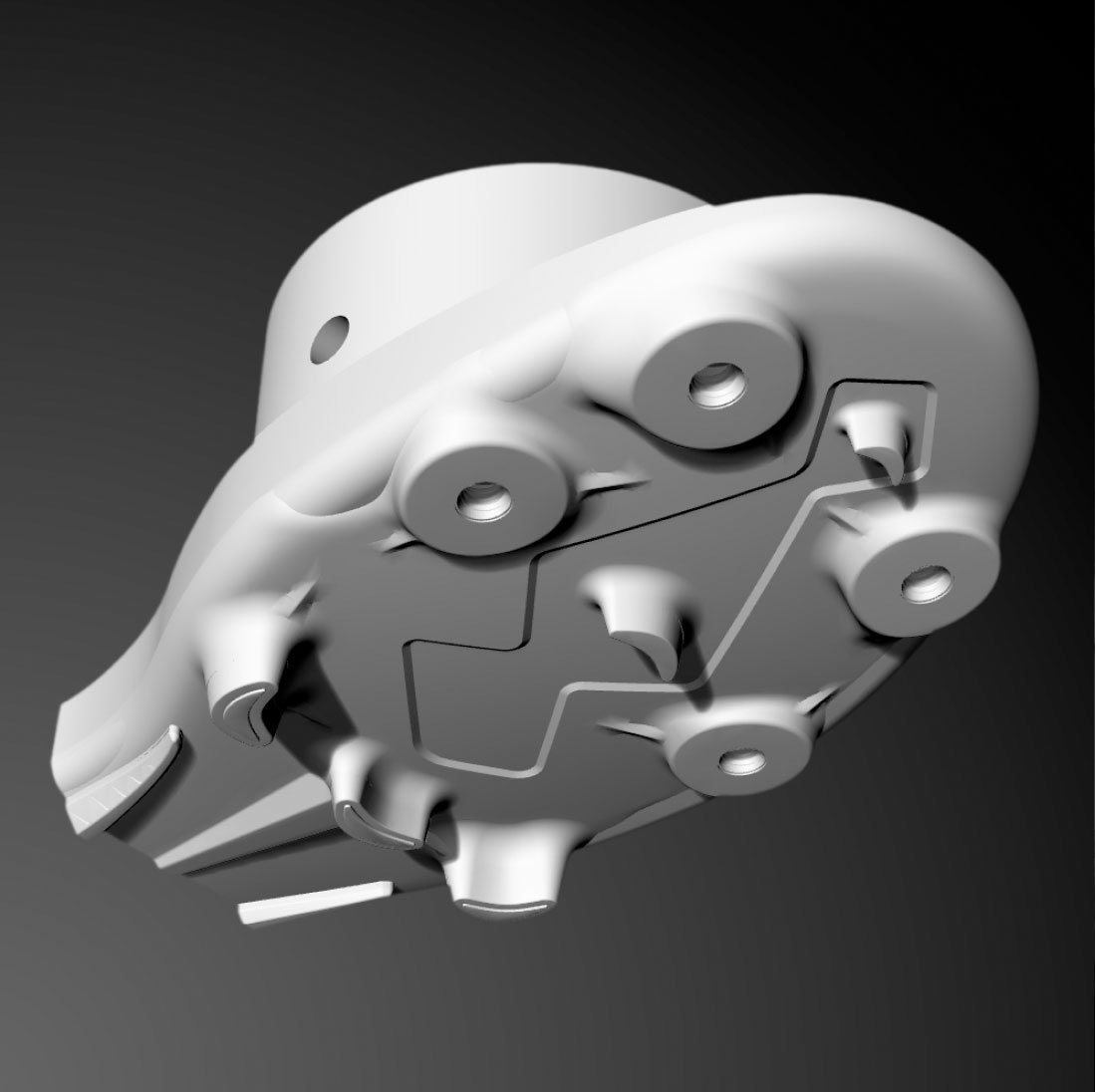

The Locol 3D team helped us modify one of our toolings to fit jigs used in testing football boot soleplates. They designed custom parts ready for 3D printing and testing, and their technical expertise and engineering background were invaluable throughout the process.

Blog

What the Latest Vietnam – USA Trade Deal Means for Footwear Brands

How Development teams at source can accelerate material development for scaling brands